Problem Understanding

The customer wants to understand what is the correct procedure for molding pieces in PPSU.The part is a cylinder, the material was chosen for its excellent resistance to and for its ability to withstand aqueous solutions of metal salts.

The customer wants to check two different molding procedures and check the best procedure.

Providing you with the Solution

To identify the presence of residual stress / tension on a piece made with sulphone-based material such as PPS, PSU PESU PES uses the phenomenon of Stress cracking.

Stress cracking is a failure that occurs when a stress and a particular chemical are present in an application at the same time, remove the stress or chemical and the problem disappears.

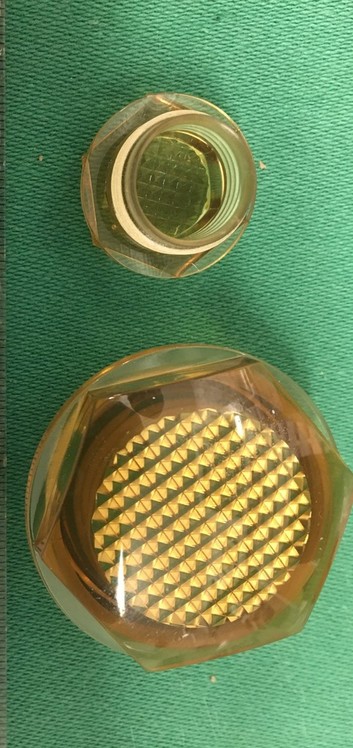

The analyzes conducted as shown in the figures shown highlight:

- Procedure A -> Optimal molding condition NO residual stress on the piece after or the test

- Procedure B -> Presence of residual stress in the piece (cracking after 60sec immersion in a suitable solvent)

WE ARE AVAILABLE TO ANALYSE YOUR SAMPLES IN ORDER TO PROVIDE YOU WITH ASSISTANCE AND SOLUTIONS TO YOUR PROBLEMS. CONTACT US TO RECEIVE INFORMATION AND THE QUOTATION OF OUR SERVICES.