The RoHS directive places limits of use that involve six substances: Lead, Mercury, Cadmium, Hexavalent chromium (Chrome VI), Polybrominated biphenyls (PBB), and Polybrominated diphenyl ether (PBDE).

Polybrominated biphenyls (PBB) and Polybrominated diphenyl ether (PBDE) are added to plastic polymers as flame retardants.

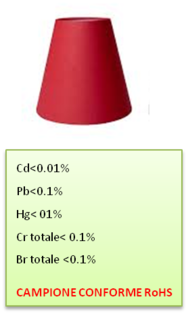

The maximum concentration of these substances is 0.1%, except for cadmium which is limited to 0.01%, by weight for each homogeneous material that is contained in the product.

The procedure that we perform in order to check the compliance with RoHS regulations related to components and/or materials consists of two stages:

Stage 1: Routine Analyses

The first stage of this procedure is sample screening with ICP-OES analysis in order to determine the total Cd, Pb and Cr. Through ion-exchange chromatography (IC) we are able to determine the total quantity of Br. This first stage allows us to investigate the presence of Pb, Cd, Cr total, Br total.

When values near the limits are assessed, we are able to move to the analysis of stage 2.

Stage 2: More accurate analyses that are necessary for the following circumstances:

• Measurement of Cr total near limits;

• Measurement of Br total near limits.

As Cr total content of the sample is near to the limit, it is necessary to check the Cr6+ content through extraction and subsequent analysis with colorimetric or polarographic methods. As for flame-retardant brominated compounds, when the Br total value determined in stage 1 reachs the limit we will be able to carry out an accurate report of the PBB and PBDE content by involving GC-MS analysis.