Problem Understanding: it is the need to determine degradation causes of polyolefin tubes.

Customer refers that the mentioned tubes show breakage problems on a batch of pipes in propylene (PP).

Providing you with the Solution: we assume that the breakage and degradation problems are due to poor oxidation resistance of the materials.

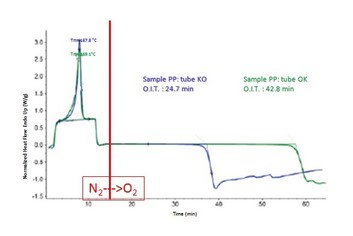

We have chosen to go for the differential scanning calorimetry (DSC) by which the index OIT (oxidation induction time) is determined.

The determination of the oxidation induction time (OIT) is a method involved to evaluate the oxidation stability of materials especially for polyolefins.

We decided to test our hypothesis of poor oxidation resistance by analysing one of the tube of the concerned batch comparing it with a tube of reference that did not show breakage problems.

The concerned tube was brought to high temperatures under inert conditions (nitrogen gas flushing in the DSC cell). After a short period of thermal balance the flow of nitrogen was replaced by oxygen. If temperature was chosen correctly, there would be no fast changing in DSC signal but after a small induction period of time the exothermic oxidation reaction began. The OIT relates to the time at which the oxidation reaction starts to show and in this case it was measured from the time that gas switched from nitrogen to oxygen state.

The analyses that were carried out on the concerned tube showed OIT lowest rate than the value carried out with reference tube.

This data confirm the hypothesis of lower oxidation resistance that the concerned tubes show under processability.

These analyses could also be developped in searching for the stabilizing additives that are contained in the concerned material.