Understanding your Problem: The need to determine the presence of lubricant additives in a sample with polyoxymethylene (POM) polymer base.

Providing your Solution: Our laboratory has developed an efficient method to determine the presence and relative percentages of lubricant additives such as PTFE, silicone oil, molybdenum disulphide and graphite in different types of polymer matrix: PP, PE, PA6, PA66, POM etc.

It is common practice in the plastics field to add lubricants to the raw polymer during the compounding phase to obtain a material with improved tribological properties. These polymers are known as self-lubricating polymers and are used in sectors where no or little external lubrication can be applied. It is also worth pointing out that the low coefficient of friction typical of these materials also makes the machining of the semi-finished pieces easier and quicker, reducing production costs.

The most common lubricants are:

-Graphite: an allotrope of carbon, which unlike diamond is a conductor of electricity. Graphite and graphite powder are useful in engineering applications for their self-lubricating properties.

-Polytetrafluoroethylene (PTFE): this is a synthetic fluoropolymer with many applications. PTFE has the lowest coefficient of friction of any known solid. Added to the polymer, it lowers the coefficient of friction by forming a lubricating film on the surface of the piece during motion.

-Molybdenum disulphide (MoS2): chemically inert, insoluble in water and resistant to acids. Molybdenum disulphide is amongst the best-known additives for self lubrication of the majority of engineering polymers; it is used as an alternative to graphite, silicone and oils.

-Silicones are organic compounds containing silicon. Silicone improves the lubrication of polymers, and is often combined with PTFE in the compound to provide excellent lubricating properties.

Our goal has been to develop a method which is able to determine the presence and percentage of these lubricant additives.

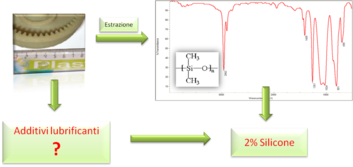

Specifically, the colour of the sample (white) directs our research to concentrate only on determining the presence of PTFE and silicone.

The qualitative analysis of the presence of PTFE is conducted via DSC thermal analysis, and its quantification via ion-exchange chromatography (IC).

Determination of silicone is performed on the extract via IR analysis to check for its presence and determine its quantity (%).

The analyses performed allowed us to ascertain that only silicone was present in the sample, with a content of 2% by weight.